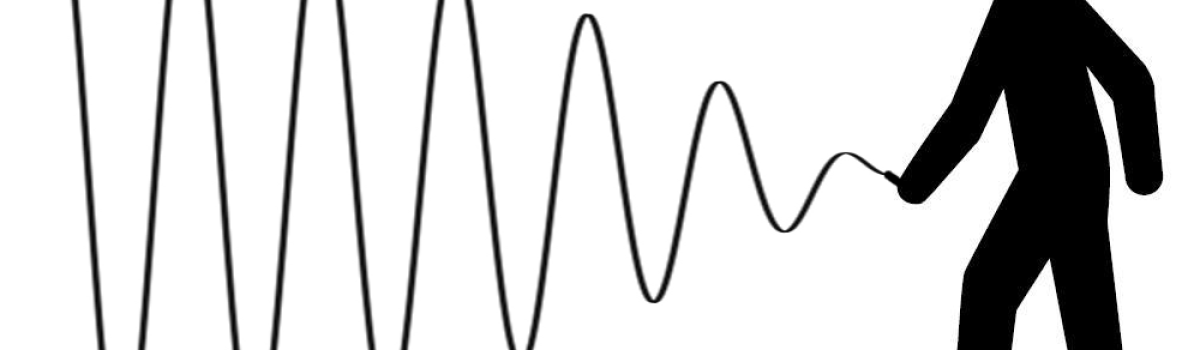

The Bullwhip Effect

We all want and love customer orders, and we would rarely have any reason to complain about them.

But be careful.

The Bullwhip Effect has been all over the news lately, for good reason. It is a dangerous phenomenon that starts with customer orders, but ends with a lot of pain for manufacturers. It is much more likely in a period of shortage, and it can slam into you just as you thought all your pandemic-related problems were over.

What is it? Well, here is what it can look like to your business : A huge spike in orders, then mass cancellations, or months of no new orders. This leaves you with inventory you do not need, no work for your shop floor, and supply orders that you do not want.

A great classic article from MIT/Sloan explains the bullwhip effect succinctly as “distorted information from one end of the supply chain to the other”. It can happen during normal times, the MIT Sloan article has some good examples. But during times of shortage, it is much more likely, and can also be much more painful.

Don’t Let This Happen To You

How can a distortion hurt your business? Let me give an example from my own experience, as a young inside sales assistant for an industrial product manufacturer. We sold through distributors, to the end customer, which is important to note. The further your company is away from the actual consumer of the product, the worse this will be for you.

At this time, due to a component part shortage, neither we nor any of our competitors could produce at our normal output levels. So we all had to wait, and our lead times started extending. For us and our competitors, what was normally a 2 week product went to 6 weeks.

Then the weirdness started. Even though we were on shortage, distributors started increasing their orders. Their logic was, I had better get my order in now, in case this gets worse. Their customers were ordering more, and they further protected them with their own orders.

And so with all this new demand, our leadtimes got pushed out yet again. We went from 6 to 13 weeks, then finally to 52 weeks! We had a full year of bookings, with firm orders. This had never happened to our company before.

We figured, this is great!! The sales team was ecstatic! The entire year was booked. Then the shortage cleared, and we started building and shipping.

And the world fell apart on us.

Distributors that received their first couple of shipments, said, thanks! And, oh by the way, now that I have these products, I don’t need my other orders. Just cancel them please.

Our cancellation policy was locked, but only within 60 days. So they honored their orders within the first 60 days, and cancelled the rest.

And we found out, that what they had ordered within those 60 days was enough to take them, and the end customers, through MUCH more than 60 days. In fact the end customers had ordered not only from our distributors, but also from our competition’s. So not only did all the orders after 60 days get cancelled, replenishment orders completely dried up for months. Which then meant no work for the shop floor.

Even worse, because this happened across competition to all of us, guess what happened to the component supplier with the original shortage. Because of course we, and our competitors, had ordered based on our (distorted) orders, plus a few “just in case” orders of our own. And then we too had to cancel it all. And this was not limited to that one component supplier — this impacted all of our material suppliers.

The Victims of the Bullwhip Effect

The hallmark of the bullwhip effect is that the farther down you are in the chain, the more dramatically you get whipped. So from customer, to distributor, to manufacturer, to raw material supplier, the pain dramatically increases. Those who cause the effect are not the ones that get punished by it.

After all, for my company, through all of this cycle, the big orders, the big cancellations — the customer demand itself had not changed at all. Their use of our product was completely steady. It was the orders, not the actual demand, that caused the bullwhip. In fact, they never really needed those orders, it was all extra. But there was no real pain on their part, all the pain was felt by our company, our competitors, and our suppliers.

And this is why, if you are a manufacturer or supplier, it is YOU that needs to be aware of this effect and how to prevent it.

The good news is that it can be prevented, or the effect can be dampened. And there are some relatively straightforward, known tactics to do so. However, that does not mean that they are easy to implement. It takes some strong leadership and controls, and the closer you are to the actual demand, the more ability you have to prevent it.

How to not get whipped by the Bullwhip Effect

- Shine a spotlight on the real upstream demand, with your customer.

2. Eliminate your own policies that make it worse

3. Realize you are in a bullwhip and limit your damage

First : Shine a spotlight on the real upstream demand, with your customer

Transparency is truly the kryptonite to the bullwhip effect. If you can clearly see what the upstream customers are consuming — not ordering! actually consuming — this is where it becomes clear to everyone that actually nothing has changed. And there is no reason to panic and place unneeded orders.

Now this is not easy. Especially if you are far down the chain, for example a supplier of leather for the shoe industry. How are you going to find out what actual consumer shoe ordering patterns are? You may have multiple layers to get through in your upstream chain.

But you likely also know your market, and that the order amounts do not make sense. Go as far as you can upstream, with your distributor, their customer, and so on. Challenge the quantities from a logical perspective, and look for signs of exaggeration.

Perhaps your distributor has implemented a special promotion, and customers are taking advantage of it to buy even more. Perhaps the customer will agree they are “extra ordering” a bit more than they should. Even if the order amounts do not change, you now have the insight to see that the bullwhip is happening and to be cautious. In the best case, everyone can agree to lower the amounts or push out the orders to be more reasonable. And you can avoid over ordering yourself to your own suppliers.

Again, this is not an easy task. But if you can do this, it has the potential to completely eliminate the bullwhip and you have dodged a very big bullet.

Second : Eliminate your own policies that make it worse.

When customers are over-ordering, you do not want to be offering sales and promotions that encourage them to buy even more than they need. The same goes for large lot sizes or minimum order quantities — anything that makes customers buy more than they actually need will amplify the bullwhip.

This is also not the time for flexible order cancellation policies. If customers see that there is zero cost to them ordering now from you 5 times, and later cancelling 4 of those orders, why would they not do it? Stricter policies will make them think twice about placing “just in case” orders.

In my experience, adjusting these internal policies can be the hardest thing to do for a business. Your lot sizes are there for a good reason, and reducing customer flexibility is never popular. But you only have limited ways to help yourself out of this bullwhip, and these two adjustments are key.

Third : Realize you are in a bullwhip and limit your damage

The biggest mistake companies make, and this was exactly the mistake we made, is viewing the demand as “real”, and not subtracting the extra ordering from their future demand. Toilet paper is the classic example these days. If I buy 300 rolls, and use 3 a week, I will not buy more for up to 100 weeks. So my local store should not expect me to purchase more for almost 2 years.

When you realize that your total amount of orders is not increasing, and instead is just very “front-end loaded”, you make better decisions. You need to expect, and plan for the dry months that will come as soon as you catch up. Make sure you spend as much effort planning for the coming falloff of demand, as you do catching up with the shortage period. And make sure decisions made in order to catch up with the shortage (buying equipment, hiring people, expanding facilities) can also make it through that dry period.

Final Thoughts

It may be strange that what can start as a simple distortion in customer orders can become so damaging to your business. This is why the bullwhip effect is a favorite of supply chain experts — it is really a fascinating topic. But it is not so fascinating when you are the victim of it. When you see it coming, recognize it and act quickly to protect your business.